| Home | AmMin | GMR | RiMG | Collectors Corner | Directory | Short Courses | |

|

|

|||||||

|

VIRTUAL FIELD TRIP TO THE KEWEENAW PENINSULA, MICHIGAN - MINING HISTORY (1840-1880)

|

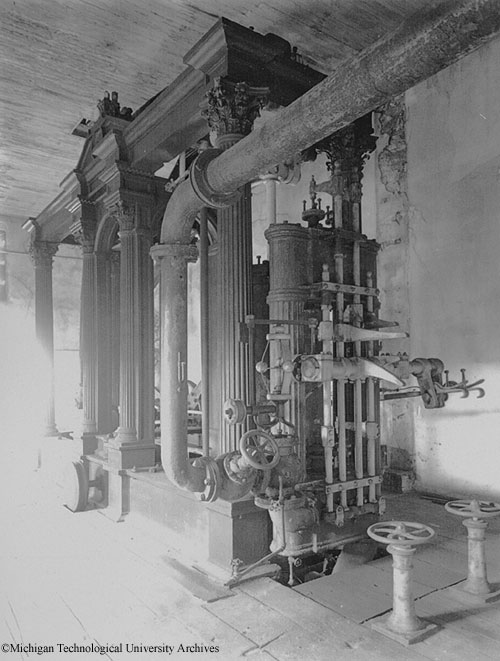

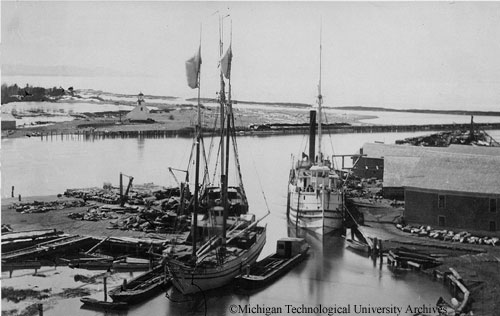

The Cass expeditions produced some of the first solid evidence of the extent of the copper district. Douglass Houghton was appointed as the first state geologist for Michigan in 1837. He persuaded the state legislature to provide $3,000.00 for a survey of the copper country. His report of 1841 aroused much interest in the area. In October 1845, he drowned during a gale on Lake Superior near Eagle River as he was completing the season's field work. The early mining history of the district is dominated by the fissure mines. These consisted of large masses of native copper in veins cutting the igneous beds. There were three major mines, the Cliff, Minesota, and Central. Many other mines were attempted, but the others all proved to be losing propositions for their investors. The two earliest mining attempts were the Pittsburg and Boston (1843-45) near Fort Wilkins and Copper Harbor near the tip of the peninsula. This mine was located on a vein of tenorite, a copper oxide. Ore worth $3,000 was mined, but unfortunately, it cost the company $25,000 to mine this ore. The Lake Superior Copper company tried to mine at Eagle River, but was unsuccessful. The area was wilderness when the first mines were discovered. To set up a mining operation, the company often had to clear land for a farm to grow food for the miners and the horses and mules used in the operations. They set up blacksmith shops to help repair their machinery and to resharpen the drills used in the mining. They were forced to construct sawmills to provide lumber for the houses as well as for the mining operations. The companies also built the houses to accommodate the miners and surface workers. They did not particularly care for this added expense, but it did give them leverage over the miners, especially in the dead of winter. They also ran some stores, but this was primarily to keep the prices that the independent storeowners could charge at a reasonable rate. While there was rampant paternalism, it was not as severe as that encountered in the Appalachian coal mines. The fissure mines produced only 2% of the total copper mined, primarily in the 1840 - 1880 time period. There was increasing production to about 50 million pounds per year in 1880, with about 80% of the total United States production coming from Michigan in this period. Production rose to 150 million pounds per year from the 1890's to 1930, but declined from 30 to 10% of the total US production as western mines (especially Butte, Montana) began producing ever greater amounts of copper. |

|

Unlike the gold mines in California later in the decade, there was a government presence in the peninsula and mining claims were leased to the prospectors. The only Federal mining law in force during this early prospecting period was the 1818 Lead Law. Initially a prospector could get a permit from the War department covering nine square miles (later reduced to one square mile) and have a 9 year lease for mining before returning the property to the government (they also were required to pay a 6% royalty). In 1847 this was changed to a system of land sales at a rate of $5.00 per acre. This rate was later lowered to the standard (for non-mineral bearing lands) land sale price of $1.25 per acre.

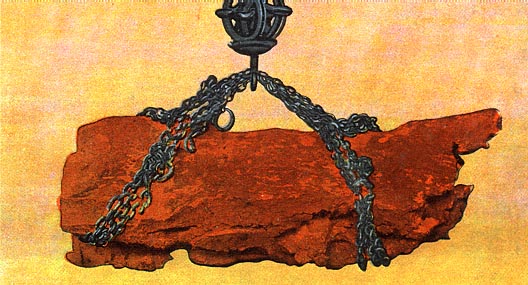

About an 8 ton piece of native copper from one of the fissure mines. Larger pieces of ore had to be chiseled into pieces that could be taken up the shafts. Although the fissure mines were the primary source of ore during the early years, they did not represent the majority of ore mined in the district. A large mass was recently removed from the bed of Lake Superior for eventual display at the Seaman Museum.

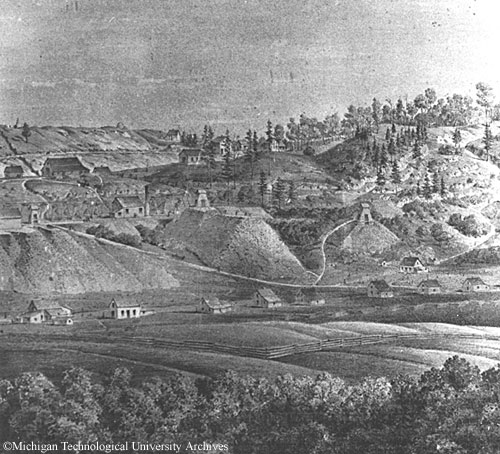

The above postcard was from the era ( early 1900's) when buildings still remained in the area of the Cliff mine. The vein was found in the cliff and an adit was driven into the hillside. Large masses of native copper were encountered that weighed up to 50 tons. The first dividend of any mine in the Keweenaw was a $60,000 dividend declared on May 21, 1849 by the Cliff. Since this area was wilderness when the first mining was going on, it was necessary for the mining companies to construct housing for the miners, erect stores and sawmills, and start farming operations for food for the miners and animals. Winter usually forced a closing of navigation on Lake Superior, so all supplies had to be brought in during the summer and fall by ship and all ore shipped out during this period.

Cliff mine (2001) ( Stop 17 - N47° 22.28' W88° 18.73'). This was the first major fissure mine in the Keweenaw (worked from 1845 -1877). The mine produced 38 million pounds of copper. It was the richest fissure mine in silver content. The Greenstone flow is the cliff forming rock in the background.

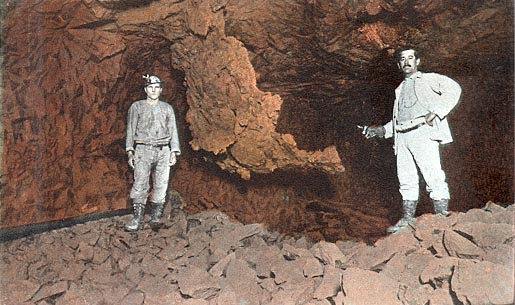

A mass of native copper hanging from the wall of a mine. This piece is approaching the largest size that could be handled without cutting up the copper in the mine. Figure on right is Captain Jose - South Range Mining Company (Baltic? Mine).

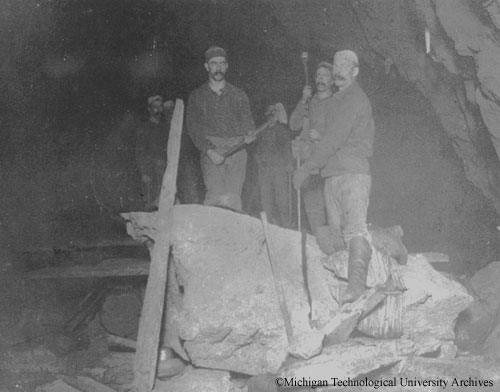

When mining mass copper, the pieces had to be chiseled to cut the ore into pieces that could be moved out of the mine. These copper chips can sometimes still be found in the mine dumps.

Central mine. Since the waste piles of rock have been broken up and the ore does not contain sulfides which would oxidize to cause acidification of the water, the rock piles are used to provide material to be crushed to gravel size for use in construction. Many rock piles in the area are being used in this manner as it saves quarrying and coarse breaking of material for use as gravel. Copper is often recovered from these operations as attempting to crush the native copper will damage crushing equipment. The Central mine was unique in that it made a profit in it's first year of operation.

The Minesota ( the one n is due to a clerical error in the original filing of the claim) mine was "discovered" by Sam Knapp in 1849. He cleared out an old Native American shaft and found at a depth of eighteen feet a six ton piece of native copper sitting on several oak timbers that had been used to raise the mass from the bottom of the shaft. The largest mass of native copper in the district was forty-five feet long with a maximum thickness of nine feet ( 520 tons) at a depth of 10 fathoms below the adit ( a horizontal tunnel accessible at the surface) level. This mass of copper required the work of 20 miners for a period of eighteen months to remove the copper. They used 2750 pounds of powder to try to reduce the mass to a more manageable size, but most of it was removed by chiseling the mass apart. The chips from this process weighed a total of 27 tons and many souvenir "fans" were created from it. Ore processing consisted largely of sorting out the pieces of native copper, hammering off any country rock, and packing the ore pieces in barrels for shipment to Detroit on ships during the summer.

|