| Home | AmMin | GMR | RiMG | Collectors Corner | Directory | Short Courses | |

|

|

|||||||

|

|

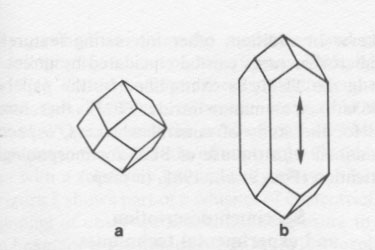

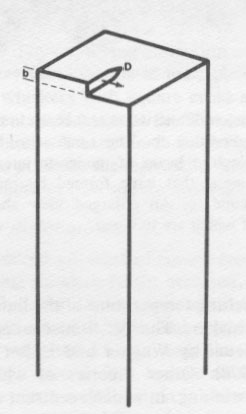

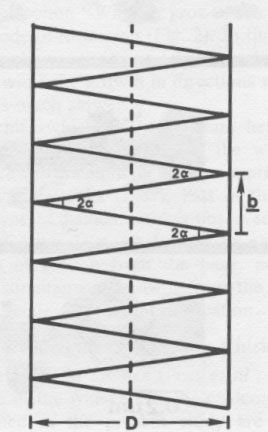

Volume 68, pages 790-803, 1983 A TEM study of fibrous cuprite (chalcotrichite): microstructures and growth mechanisms DAVID R. VEBLEN Department of Earth and Planetary Sciences AND JEFFREY E. POST Department of Geological Sciences Abstract A specimen of the fibrous, or whisker, variety of cuprite ("chalcotrichite") was examined with transmission electron microscopy (TEM). Of several morphologically distinct whisker types, only those with square cross sections were observed to contain screw dislocations. The dislocations generally are straight and close to the whisker axis, although in some cases the dislocations approach the crystal surface, and in one case a helical dislocation was observed. In addition, one whisker with a very large Burgers vector contained a hollow axial tube, in accordance with Frank's (1951) theory. The presence of axial screw dislocations in almost all of the chalcotrichite whiskers of square cross section indicates that they formed by a spiral growth mechanism, thus accounting for their extreme elongation. A variety of ribbon-shaped whiskers are also present in the specimen. These include not only pure cuprite ribbons, but also composite whiskers containing epitaxial cuprite and native Cu metal. The latter type, which commonly occurs as double whiskers in parallel growth, is curled, probably as a result of differential contraction of the cuprite and Cu metal upon cooling from the temperature of growth. The growth mechanisms of the chalcotrichite ribbons cannot be determined from the available observations, but it is likely that several complex mechanisms operated, since there are a variety of different whisker types present. This variety also suggests that it is the growth conditions (temperature, pressure, vapor composition, degree of supersaturation) that determine whether whiskers or equidimensional crystals will grow, rather than the specific mechanisms of whisker growth. Introduction It was recognized originally by Pierre Curie (1894) that the morphological symmetry of a crystal depends not only on the symmetry of the crystal structure, but also on the symmetry of the environment in which the crystal is grown. Thus, when grown in an isotropic environment, a crystal having cubic symmetry will also exhibit morphology that can be characterized by one of the cubic point groups. When grown in an anisotropic environment, however, a cubic crystal may become elongated in one direction, for example, producing a crystal shape that has symmetry lower than cubic, as shown in Figure 1 (Kostov, 1968; Shafranovskii, 1957, chapter 3). Even though crystal shape can be influenced by the growth medium, it is perhaps surprising that minerals having cubic symmetry, as well as minerals belonging to other crystal systems, in some cases occur as thin crystals that are grossly elongated in one direction, in some cases having aspect ratios of thousands to one. Such filamentary crystals are referred to by materials scientists as "whiskers." Because they are commonly very strong, compared to crystals of other morphologies (Zoltai, 1981), and because of their uses in composite materials technology (Beardmore et al., 1980; Broutman and Krock, 1967), whiskers have received extensive treatment in the applied physics and crystal growth literature. It is the purpose of this paper to review some of the structural observations on synthetic whiskers and to present new transmission electron microscopic (TEM) observations on whiskers of the cubic mineral cuprite, which are referred to by the varietal name "chalcotrichite." These results are discussed in light of possible growth mechanisms for mineral whiskers. In a related study (Post et al., 1981; and in preparation), we present more detailed morphological data on chalcotrichite, based on scanning electron microscopy (SEM). Whisker growth mechanisms About forty years ago, it was recognized that crystal growth from a vapor phase commonly occurs at levels of supersaturation far below those theoretically required for the nucleation of growth steps on a crystal surface. To explain these anomalous results, Frank (1949) proposed a mechanism of growth in which a screw dislocation emerging from a crystal face provides a permanent growth step. Such a spiral growth mechanism eliminates the need for nucleation of new layers on a crystal surface and therefore reduces considerably the degree of supersaturation required for crystal growth. Observations of spiral ledges on growth faces of a wide range of compounds suggest that Frank's spiral growth mechanism is, in fact, an important one (see, for example, Verma and Krishna, 1966). Spiral growth was later invoked by Sears (1953, 1955) to explain the growth of whiskers. According to this theory, a crystal face with an emergent screw dislocation can add on new material much faster than other crystal faces, resulting in extreme crystal elongation in the direction of rapid growth. A diagrammatic sketch of this mechanism is shown in Figure 2. The spiral growth theory of whisker formation requires that each whisker contain at least one dislocation having some screw component parallel to the axis of the whisker. Such axial imperfections have, in fact, been observed directly with decoration and optical microscopy techniques in alkali halide whiskers (NaCl, KCl, LiF, and KBr: Amelinckx, 1958a,b) and with TEM methods in whiskers of aluminum nitride (Drum and Mitchell, 1964; Drum, 1965a,b), tellurium (Furuta et al., 1972), copper (Hasiguti et al., 1970), and silicon carbide (Shaffer, 1967). In addition, it was shown by Eshelby (1953) that the strain field associated with a screw dislocation can twist a crystal about an axis parallel to the defect. The existence and, in some cases, the Burgers vectors, of axial screw dislocations have been inferred from X-ray observations of this "Eshelby twist" in a number of different whisker materials: alpha alumina (Dragsdorf and Webb, 1958), chalcotrichite (Shlichta, 1957; Kirov and Atanassov, 1970), silver, palladium (Webb, 1958), and tin (Treuting, 1956; Webb et al., 1957). Although some types of whiskers do contain axial dislocations with a screw component, others do not. Attempts to observe such defects directly with TEM methods or indirectly by recognition of Eshelby twist have produced negative results for many different types of whiskers, including those of some materials that under different growth conditions do exhibit such dislocations. Whiskers without dislocations include manganese, cobalt, nickel, zinc, silver, cadmium, tin (Webb, 1958; Webb et al., 1957), copper (Webb, 1958; Yamamoto et al., 1968; Regis, 1969), iron (Webb, 1958; Regis, 1969), alpha alumina (Gelles and Binnie, 1969), aluminum nitride (Berezhkova et al., 1972), manganese arsenide (Bärner and Berg, 1979), and silicon carbide (Shaffer, 1967). In these cases, a spiral growth mechanism cannot be invoked as the cause of crystal elongation. It appears instead that whiskers of this type commonly grow by a Vapor-Liquid-Solid (VLS) mechanism, in which a drop of liquid at the tip of a whisker controls growth. Atoms from the vapor perferentially condense into or are transported along the crystal surface to the liquid droplet and then crystallize into the growing whisker tip. Impurities play an important role in this type of whisker growth by lowering the melting temperature of the liquid relative to that of the whisker. The VLS mechanism has been described in detail by Wagner and Ellis (1965) and by Givargizov (1978). Other theories of whisker growth include gross twinning, in which reentrant angles on the surfaces of twins provide preferential atomic attachment sites; poisoning of crystal surfaces, which prevents growth in certain directions; and surface diffusion mechanisms, as described by Schwoebel and Shipsey (1966) and Schwoebel (1967). The presence or absence of axial dislocations clearly is important for determining the likely growth mechanisms for whiskers. In addition, other interesting features of whisker microstructures can be elucidated by direct observation in the TEM, as exemplified by the papers of Drum (1965a,b) on aluminum nitride. TEM is therefore an ideal tool for the study of mineral whiskers, especially when combined with the use of SEM for morphological characterization (Post et al., 1981, in prep.).

Specimen description and experimental techniques A chalcotrichite (Cu2O) specimen from the Ray Mine, Arizona, was used in this study; the specimen is from the collection of S. Turner and is typical of material from Ray. This material was chosen because it consists of extremely fine whiskers, many of which are thin enough to be transparent in the TEM. The whiskers are extremely flexible and move around when subjected to light air currents. SEM examination demonstrated a great diversity of whisker morphologies in this specimen, and energy dispersive X-ray analysis in both the SEM and TEM revealed no cations other than Cu. Specimens for TEM study were prepared by lightly grinding the chalcotrichite under acetone in an agate mortar and depositing the whiskers on a holey carbon TEM grid. The whiskers were studied in a Philips 400T microscope operated at 100 kV and using standard electron diffraction and single-beam bright and dark field techniques, as well as multiple-beam high-resolution imaging.

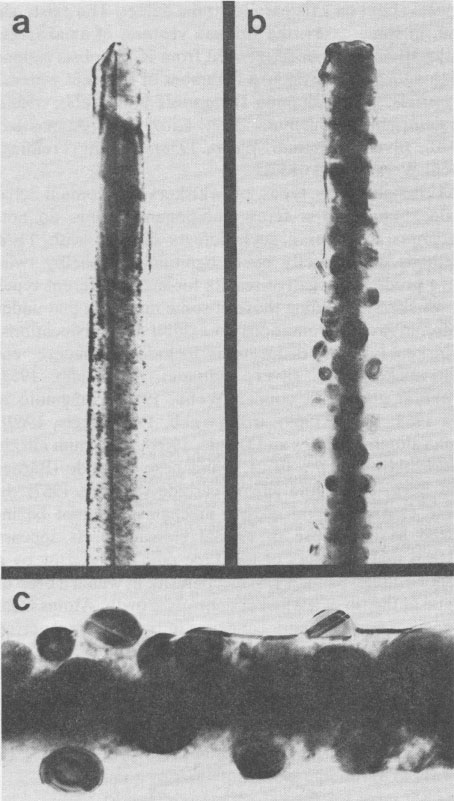

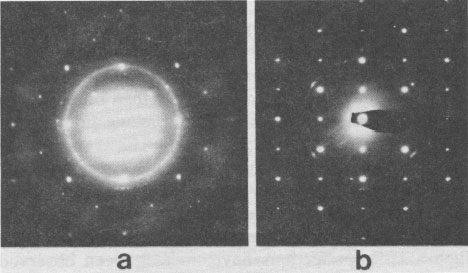

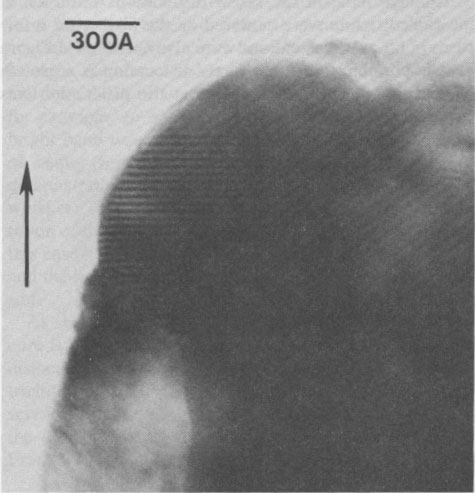

Reduction to Cu metal It is well known that the electron beam of a TEM has a reducing effect on the sample. A beautiful demonstration of this effect is provided by the in situ reduction of WO3-X, which involves the nucleation and growth of crystallographic shear planes (Iijima, 1975; Allpress et al., 1971). Reduction of cuprite also occurs in the electron microscope. However, whereas reasonable reduction rates of WO3-X require the removal of the TEM condenser aperture, the reduction of cuprite to Cu metal occurs even with a relatively low-intensity electron beam. Figure 3 shows part of a whisker of chalcotrichite at the beginning of observation and after exposure to the electron beam for a few minutes. Exposure has resulted in the formation of more-or-less spherical crystals on the surface of the whisker; some of the crystals exhibit contrast that probably arises from twinning. The particles can be identified from diffraction patterns as copper metal. Figure 4a shows a [100] diffraction pattern of partially reduced chalcotrichite, in which the diffraction from Cu forms rings and that from cuprite forms sharp spots; this pattern indicates that the Cu is nearly randomly oriented. Such random orientation occurs when irradiation is relatively rapid. When reduction occurs in a weaker beam, preferred orientation of the Cu crystals occurs, as a result of epitaxial growth; Figure 4b is a [110] diffraction pattern of the whisker shown in Figure 3, exhibiting non-random Cu orientation. Where Cu growth is epitaxial, moiré fringes resulting from the overlapping of the copper and cuprite structures can be observed under multiple-beam bright field conditions (Fig. 5).

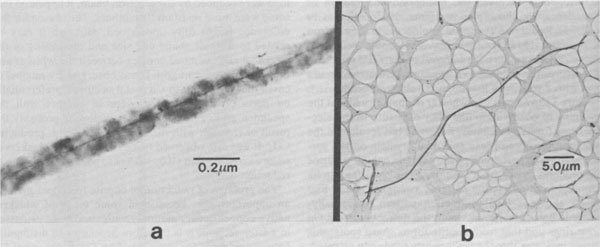

Although most chalcotrichite whiskers that were examined were reduced by the electron beam, it appeared that some were more resistant than others. The reason for this difference is not fully understood, although it may be related to whisker shape and size and the quality of the electrical and chemical contact between the whisker and the specimen support grid. It was observed in a number of cases that reduction to Cu metal occurred preferentially on parts of whiskers that were in contact with the specimen grid. This enhanced reduction is probably the result of reaction with the carbon of the grid, producing CO2. It was also observed that extremely thin whiskers of square cross section (100-300Å) are particularly prone to reduction damage. The problem of reduction of cuprite to copper metal is an important one, because in some types of whiskers native copper occurs naturally with cuprite, as discussed in a later section. It is therefore necessary to distinguish between primary Cu and secondary Cu that is produced by reduction radiation damage in the electron microscope. Dislocations in whiskers of square cross section Examination in the SEM of the chalcotrichite sample used in this study indicates that there are several morphologically distinct whisker types (Post et al., 1981, in prep.). These can be separated into two broad categories: (1) whiskers with square or nearly square rectangular cross sections, which can occur as individual crystals or in a parallel growth habit; and (2) ribbons, in which the thickness is much less than the width; there are several types of ribbons, as discussed later. These two categories of whiskers could be distinguished readily in the TEM by observing the whisker outlines while tilting the stage to high angles and by observing extinction contours characteristic of very thin crystals in the ribbons. In both the ribbons and whiskers with square cross section, diffraction experiments indicate that the fiber axis is parallel to an a-axis, which will henceforth be designated [001]. In this section, we discuss the microstructures present in the whiskers of more-or-less square cross section. Axial screw dislocations Several hundred whiskers of square cross section were examined using standard bright field and, in some cases, dark field techniques. Dislocations were observed in most of these whiskers (about 90%), and experiments in which the whiskers were tilted about their axes confirmed that the dislocations were, in fact, located on the whisker axis in most cases; such a dislocation is shown in Figure 6a, where it appears as a dark line. A dislocation can also be seen in the whisker in Figure 3a. Figure 6b is an overview of the whisker in Figure 6a, giving an idea of the high aspect ratio of some of the whiskers and demonstrating their flexibility. Only those square whiskers that were very thin could be examined for dislocations, because the thicker ones are not transparent to the electrons (the whisker of Figure 6 is approximately 0.15 µm in diameter). Thus, it is not known whether or not the larger whiskers contain multiple dislocations, as can be the case for thicker whiskers of NaCl (Amelinckx, 1958b) and some other materials. Axial dislocations were observed not only in individual whiskers, but also in those occurring in parallel growth.

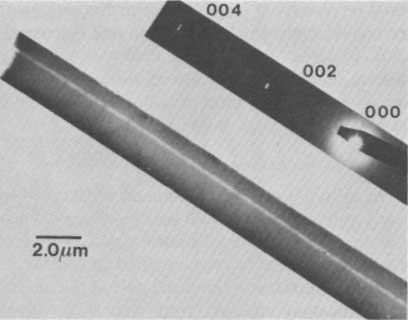

Single-beam dark-field experiments showed that the Burgers vectors of the axial dislocations are [001], or multiples thereof (i.e., parallel to the whisker axes), demonstrating that they are pure screw dislocations. This confirms the X-ray experiments of Kirov and Atanasov (1970), who measured the Eshelby twist in a number of chalcotrichite whiskers. Because the amount of twisting is related to the displacement of the axial dislocation, Kirov and Atanosov were able to ascertain that the Burgers vectors ranged from 8.6Å to 43Å, corresponding to displacements from 2a to l0a (the a crystallographic axis for cuprite is 4.27Å). Although most of the screw dislocations observed in the chalcotrichite were centered on the fiber axes, a few cases of off-axis dislocations were also noted, as in Figure 7. It is possible that the off-axis dislocation is a growth feature, but it is also possible that the dislocation was initially on the whisker axis and later moved toward the crystal surface through dislocation glide during annealing or during deformation associated with sample preparation. Removal of dislocations from the whiskers by such glide could explain why some of the square whiskers were observed to contain no axial dislocations. Hollow axial cores It was shown theoretically by Frank (1951) that screw dislocations with large Burgers vectors should take the form of hollow tubes, in order to minimize strain in the crystal. Such hollow cores have been observed optically in alpha alumina whiskers (Dragsdorf and Webb, 1958) and with SEM in synthetic phlogopite (Baronnet, 1972), for example. In one chalcotrichite whisker, a relatively bright band was observed to run parallel to, but slightly off-center from the fiber axis (Fig. 8). Tilting of the crystal demonstrated that this feature is, in fact, internal to the whisker. This observation is consistent with the interpretation of the bright band as a hollow core. The whisker in this case has a cross sectional diagonal of about 2.25 µm, and the diameter of the hollow core is approximately 0.12 µm. As shown by Frank (1951), the size of the hollow axial core is related to the length of the Burgers vector of the dislocation. In the next section, we show that the chalcotrichite whisker shown in Figure 8 does, indeed, possess a screw dislocation of very large Burgers vector and that the diameter of the axial tube is reasonable in light of Frank's theory. Diffraction patterns and Burgers vectors of screw-dislocated whiskers It has long been known that helical structures produce diffraction patterns in which reciprocal lattice rows form X's (Wilson, 1949; Cochran et al., 1952). Historically, it is of interest that diffraction patterns from the double-helical structure of deoxyribonucleic acid (DNA) produce such "X" diffraction patterns (see Wilkins et al., 1953, for example). Indeed, it was this recognition that led to early helical models for DNA and that finally allowed Watson and Crick (1953) to solve the DNA structure. In a whisker containing a [001] screw dislocation, the (001) planes are not truly planar or parallel, but rather should form a helix, as shown schematically in Figure 9. Therefore, the diffraction patterns of such screw-dislocated whiskers should show the "X" characteristic of helical structures, and in principle it should be possible to determine the Burgers vector of the dislocation if the diameter of the whisker is also known. As shown by Cochran et al. (1952) and Wilkins et al. (1953), the angle between the arms of the "X" on the diffraction pattern is approximately equal to twice the pitch of the helix. Thus, the angle 2α in Figure 9 can be determined approximately by measuring the diffraction pattern. The inset in Figure 8 is part of a [110] electron diffraction pattern from the hollow-cored whisker. The splitting of the diffractions is related to the helical structure of the whisker, and the angle 2α is approximately 1.6°. With reference to Figure 9, it easily can be shown that b=2D tan α (1) where b is the Burgers vector of the screw dislocation, D is the whisker diameter, and α is the pitch of the helix. For the whisker of Figure 8, α = 0.8° and D = 2.25 µm. Therefore, b = 0.0628µm = 628Å. This obviously is a very large Burgers vector, corresponding to roughly 150 times the cuprite cell parameter and much larger than any of those reported by Kirov and Atanasov (1970). It is not at all surprising that a whisker with a dislocation of such large Burgers vector should contain an axial tube, rather than being completely solid! Frank (1951) gives the approximate equilibrium radius of an axial tube as

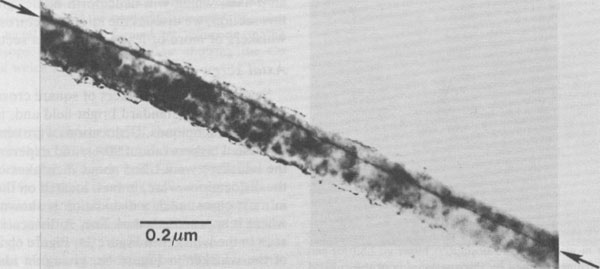

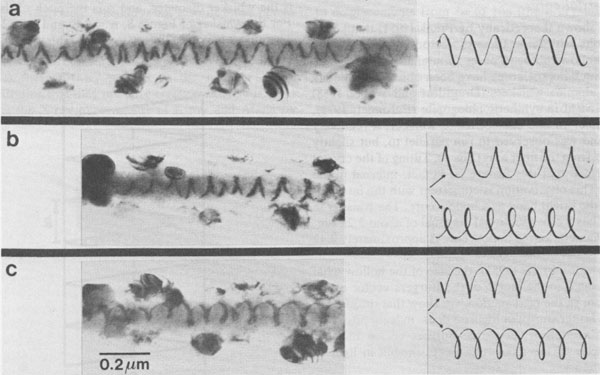

µb2 where µ is the rigidity modulus of the material, b is the Burgers vector of the dislocation, and γ is the surface energy of the material. From this relationship we can calculate that for the tube diameter and Burgers vector observed for the whisker of Figure 8, the ratio γ/µ is approximately 26 x 10-8 cm. Since this value is of the right order of magnitude (see Frank, 1951), it would appear that the Burgers vector and tube diameter in this whisker are not inconsistent with the theory. In whiskers not exhibiting obvious axial tubes, very small splitting of diffractions could in a few cases be seen at large values of TEM camera length (i.e., with the diffraction pattern blown up very large). In most cases, however, no splitting associated with the helical structure could be observed, consistent with Burgers vectors that are considerably smaller than the one discussed above. Thus, in agreement with the theory of Frank (1951), it appears that screw dislocations with small Burgers vectors do not take the form of hollow axial tubes, whereas those with very large Burgers vectors do. Helical dislocations The most unusual observation on whiskers of square or nearly square cross section was made on a whisker that contained a helical dislocation for part of its length; the remainder of the whisker contained an ordinary, straight axial screw dislocation, but the part of the crystal where the dislocation changed from helical to straight was obscured by the specimen support grid. Figure 10a shows the helical dislocation as viewed with the whisker normal to the electron beam; it appears as an irregular zigzagged line. Figures 10b and 10c show the dislocation with the whisker tilted in opposite senses, so that it is no longer normal to the TEM axis. As shown by Thomas and Whelan (1959) and in Figure 10, the closure of the dislocation into cusps and loops on opposite sides of the whisker for the two senses of tilt demonstrates that the dislocation is, indeed, a helix, rather than simply a planar zigzag.

Helical dislocations in bulk specimens have been observed in heat-treated fluorite (Bontinck and Amelinckx, 1957; Amelinckx et al., 1957), in silicon (Dash, 1958), in germanium (Tweet, 1958), in alkali halides (Barber et al., 1957), and in copper-aluminum alloys (Thomas and Whelan, 1959). In addition, Drum (1965a) observed rare zigzagged dislocations in aluminum nitride whiskers that were probably also helical dislocations. Several different formation mechanisms have been proposed for helical dislocations. In the bulk materials noted above, the mechanism is probably climb or combined glide and climb of initially straight dislocations that have a screw component; this process is associated with the condensation of vacancies onto the dislocation and appears to occur during annealing in materials with large supersaturations of vacancies (see detailed discussion by Thomas and Whelan, 1959). Amelinckx et al. (1957) suggested that some whiskers might form on a substrate at the positions of emergent screw dislocations. These whiskers would grow from the base, spiraling as they grow, and the result would be whiskers containing helical dislocations. Webb et al. (1957) proposed a mechanism for producing whiskers with helical morphology in which a screw dislocation follows a spiral path as the whisker grows from the tip; this mechanism might also be applicable to the formation of helical dislocations in straight whiskers, although it is not clear what would cause the spiral motion. Because of the rarity of helical dislocations, compared to straight axial dislocations, it would appear that the most likely mechanism of helical dislocation formation in chalcotrichite is that proposed by Amelinckx et al. (1957). Growth mechanisms of the square whiskers Because nearly all of the chalcotrichite whiskers with square cross sections contain straight axial screw dislocations, it is very likely that these dislocations play an important role in the formation of these whiskers. Specifically, spiral growth about the screw dislocation, as discussed in the section "Whisker growth mechanisms," is the likely mode of formation (Fig. 2). In this case, rapid growth takes place at the crystal tip in the direction of the dislocation, while the growth in directions normal to the dislocation is much slower. Chalcotrichite whiskers that contain helical dislocations might form by nucleation of the whisker at an emergent screw dislocation on another cuprite crystal, as proposed by Amelinckx (1957). Part of the whisker in which this type of dislocation was observed contained a straight axial dislocation. This might be explained by a combination of growth from the base, producing the helix, with simultaneous growth from the whisker tip, producing a section of straight dislocation. Microstructures in ribbon whiskers As shown by SEM studies (Post et al., 1981; and in prep.), some of the whiskers in the chalcotrichite specimen examined in the present study are shaped like ribbons, rather than having square or nearly square cross sections. In some cases these ribbons are extremely thin, resulting in striking contrast from bend contours (compare with Figure 12.4 in Hirsch et al., 1977, for example) and a mottling that apparently results from minor orientation variations (Fig. 11). Very thin ribbons can be distinguished from square whiskers either by tilting experiments or by observation of such thin-crystal contrast. The crystal in Figure 11 is about 2.4 µm wide but is probably not more than a few hundred ängströms thick; hence, it is a ribbon.

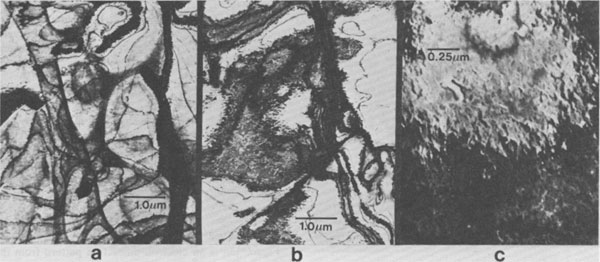

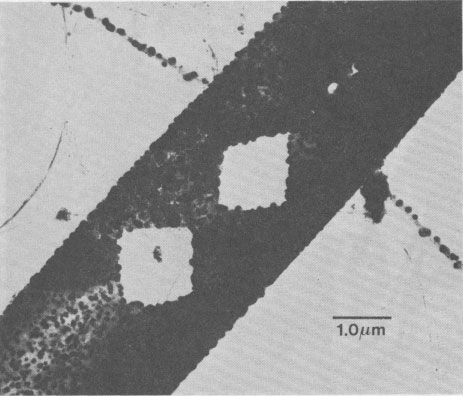

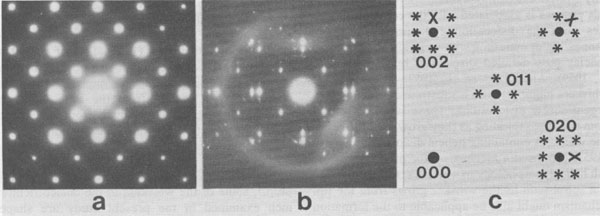

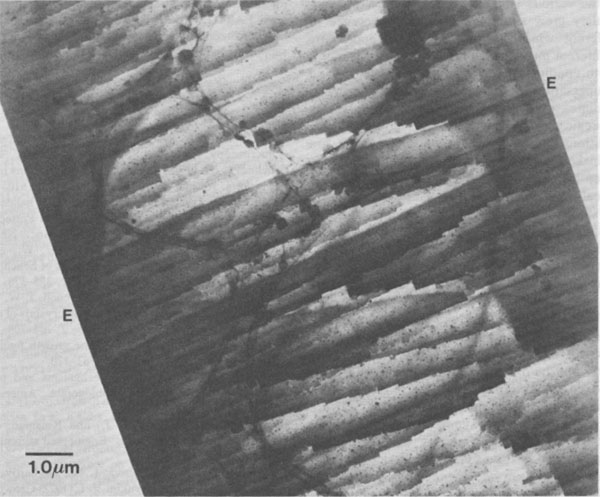

The presence of both square and ribbon whiskers intimately intergrown in the same chalcotrichite sample may seem odd, but it is, in fact, similar to the aluminum nitride studied by Drum and Mitchell (1964) and Drum (1965a, b), who found that there were several distinct whisker types coexisting in the same synthesis product. Since whisker morphology and microstructures appear to reflect the mechanisms of growth, coexistence of several whisker types probably indicates that there were several different growth mechanisms operating, as discussed later. Defects in ribbons The chalcotrichite ribbons examined in this study contained no observable dislocations or planar defects, except for fractures and occasional diamond-shaped holes (Fig. 12). It is therefore unlikely that the formation of the ribbons involved a screw dislocation spiral growth mechanism. Possible ribbon growth mechanisms are discussed below. Ribbon diffraction patterns and structure Figure 13a is an electron diffraction pattern from the ribbon in Figure 12. The diffractions are sharp, and there is no evidence of diffraction from Cu metal (the pattern was taken with a very low electron flux before observable reduction occurred). This diffraction pattern contrasts markedly with patterns from some other ribbons, such as the one in Figure 13b; these patterns show intense reflections from Cu metal, even when recorded in the same fashion as the pattern in Figure 13a and from ribbons that have no visible particles on them and that are on grids that have not been in the electron microscope for long. Unlike the diffraction patterns of Figure 4, in which Cu crystals produced by reduction of cuprite in the TEM are randomly or imperfectly oriented with respect to the cuprite, the diffraction pattern in Figure 13b demonstrates an almost rigorous orientation relationship between the Cu and cuprite structures: the a-axes of the two phases are parallel. In addition to diffractions from cuprite and Cu, Figure 13b shows numerous spots arising from multiple diffraction, as indicated in Figure 13c. (For a similar case in a synthetic system, see the diffraction effects from overlapping Mg2Si and Al in Hirsch et al., 1977, p. 151-152). Selected area electron diffraction experiments indicate that patterns such as that in Figure 13b do not vary in different parts of a ribbon (except in orientation). These results suggest that while some of the ribbons are pure cuprite, others are composite whiskers that consist of an epitaxial intergrowth of cuprite and native copper. This is undoubtedly the first known case of naturally occurring bimetallic strips (except that in this case one of the phases is not a metal). In fact, there is both SEM (Post et al., 1981, in prep.) and TEM evidence that some ribbons are slightly curled, possibly as a result of differential contraction of the cuprite and Cu metal. This curling is discussed in the next section.

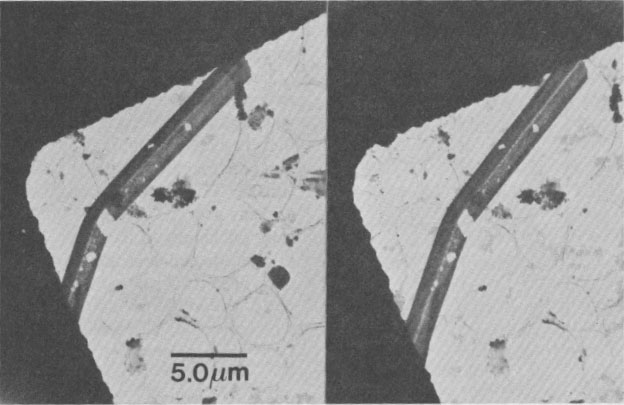

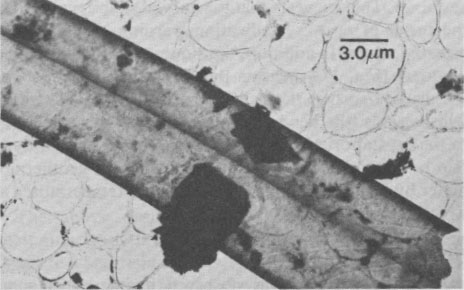

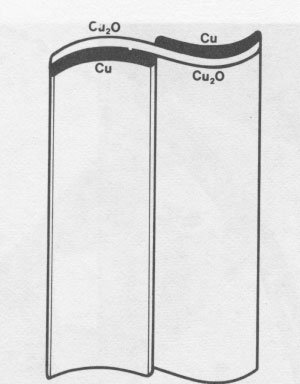

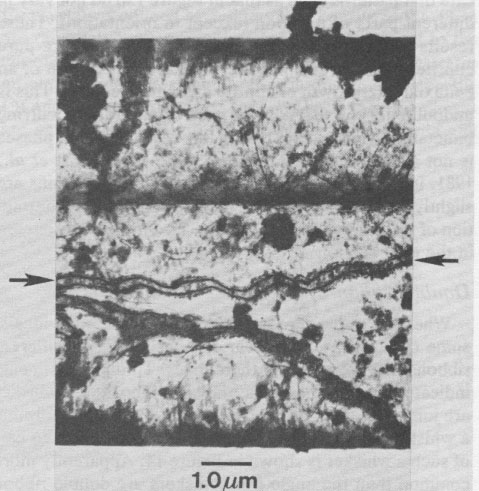

Double-ribbon whiskers Whereas some ribbons occur as single individuals, some other whiskers appear to consist of two different ribbons that are joined at their edges. Tilting experiments indicate that in some cases, the two ribbons of a whisker are joined together at approximately a 90° angle, forming a whisker that is shaped like an angle iron. A stereo pair of such a whisker is shown in Figure 14. Apparently more common than the angle iron whiskers are double-ribbon whiskers in which the two ribbons are roughly parallel and joined along their edges (Fig. 15). In the TEM the place where the two ribbons meet appears as a pronounced linear feature, and care must be exercised so as not to interpret the image as that of a whisker of square cross section with an axial screw dislocation. Electron diffraction patterns of these double whiskers indicate that they are composites of cuprite and Cu metal. SEM images and stereographic TEM photographs further suggest that the two ribbons that make up such a whisker are warped in opposite senses. The darkened contrast at the edges and near the central linear feature of the whisker in Figure 15 may also result from such warping. A schematic model of one possible configuration for this complicated whisker type is shown in Figure 16. A few cases have been observed in the SEM and TEM in which double-ribbon whiskers have partially separated into two single ribbons. It is possible, then, that the individual cuprite and Cu metal composite ribbons that were observed originated as double-ribbon whiskers and have since pulled apart, whereas the pure cuprite whiskers initially grew as individual ribbons. The curious warping of the composite whiskers could be a growth feature or could result from curling of the thin sheets during cooling, as a result of differential contraction of the cuprite and Cu metal. Selected area electron diffraction patterns taken in several places across the whisker in Figure 15 indicate that not only is the crystal morphologically S-shaped in cross section, but that the cuprite and Cu metal lattices are also warped into an S shape (i.e., that the (100) planes are probably parallel to the crystal surfaces). This suggests that the curved shape is probably the result of post-crystallization warping, rather than a growth feature. In addition, the sinuous character of bend contours (Fig. 17) suggests that in places these ribbons are warped so that they slightly undulate parallel to the whisker axis (the bend contour position is very sensitive to the crystal orientation). A rather bizarre possibility is that one could use these bent whiskers as a geothermometer by heating them and recording the temperatures at which they become planar!

Ribbon surface steps? A curious pattern was observed in images of some ribbons; an example is shown in Figure 18. The contrast of these features is similar to the contrast arising from surface steps on MgO crystals in bright field experiments by Lehmpfuhl and Uchida (1979, 1980). These steps were determined to be of monatomic height (2.1A) and low multiples of monatomic height. Although it cannot be demonstrated rigorously from the present experiments, it is most likely that the contrast in Figure 18 is also related to very small surface steps. The steps in Figure 18 appear to be roughly aligned in two orientations that are approximately 85° from the whisker axis. Careful examination of the features shows that they are not straight but are composed of segments that are roughly parallel to (001) and (010) (taking the whisker axis as [001]). The contrast in the micrograph darkens near the step edges; it is possible that this arises from thickening of the steps, from strain near the edges, or from detachment and curling away of the steps from the whisker substrate. Since the whisker of Figure 18 is a composite of cuprite and Cu metal, it is not known whether the steps are Cu on a cuprite substrate, cuprite steps on a cuprite substrate, or some other combination. Clearly, further study of whiskers that exhibit contrast of this sort would be of interest for electron diffraction and imaging theory. Growth mechanisms of the ribbon whiskers As discussed previously, the growth of the chalcotrichite whiskers with square cross sections is almost certainly governed by a spiral growth mechanism involving axial screw dislocations. The growth mechanisms that control the formation of ribbons are much more difficult to assess, however, since these whiskers are invariably completely free of dislocations. Thus, their formation cannot be attributed to spiral growth.

As discussed in the section "Whisker growth mechanisms," growth by a Vapor-Liquid-Solid (VLS) mechanism can result in whiskers. Indeed, the presence of twocomponent whiskers (cuprite plus Cu metal) might at first suggest that at least some of the ribbons grew by such a mechanism. A whisker grown by VLS methods generally consists of a single compound throughout its length, however, with the second compound only at the tip (where the liquid droplet freezes upon cooling from growth conditions); this is not the case of the cuprite-Cu composites observed in this study. Furthermore, simple VLS growth cannot explain the ribbon morphology in a cubic mineral or the fact that many of the composite whiskers are double ribbons. Clearly, more than simple VLS growth is involved in the formation of the several types of chalcotrichite ribbons. It is possible that some combination of VLS and surface diffusion phenomena control growth of some ribbons. The reentrant surfaces along the axes of the double ribbon whiskers likewise might provide preferential atomic attachment sites, similar to those that control whisker growth by gross twinning mechanisms. Unfortunately, there is no obvious single answer to the question of growth mechanisms. The fact that there is diversity in the types of ribbons observed in this specimen suggests, in fact, that there are also diverse mechanisms by which they grew. Finally, it seems very likely that at least some types of the chalcotrichite ribbons grew by unknown mechanisms that have not yet been considered; it is probably safe to say that whisker growth theory is not yet developed enough to explain all of the observations presented in the preceding pages. Discussion The above descriptions of chalcotrichite whiskers, their microstructures, and their growth mechanisms demonstrate a surprising diversity in whisker types, especially considering that all of the whiskers are from the same small sample. Although there is no guarantee that all of the whisker types grew simultaneously, it has been observed in other systems (aluminum nitride-Drum, 1965a, b) that several different whisker morphologies can grow in the same synthesis run. In the case of the chalcotrichite examined in this study, extreme entanglement and intertwining of the various whisker types also strongly suggests that they grew simultaneously. The presence of several different whisker types that have apparently grown by different mechanisms therefore suggests that it is the growth conditions (T, P, vapor composition, and degree of supersaturation) that determine whether whisker or equidimensional crystal growth will occur, rather than the specific mechanisms of whisker growth. Thus, when conditions appropriate for whisker growth are attained, whiskers form by a variety of mechanisms. This paper has described a foray into the world of morphological crystallography. This may be unusual in this day of sophisticated scientific instruments, and it is fitting, perhaps, that we close with a brief discussion of relevant ideas from the past. First, it is clear from the great successes in predicting crystal morphology from crystal structure that structure alone in many cases must determine morphology (for example, Donnay and Harker, 1937; Hartman and Perdok, 1956; Dowty, 1976, 1977; Hartman, 1977). In some cases, however, as in the present case of whisker growth in cuprite, crystal structure is clearly not the only morphological determinant. As mentioned in the introduction, Pierre Curie (1894) showed that the symmetry properties of a crystal are dependent not only on the symmetry of the crystal structure, but also on the symmetry of the medium surrounding the crystal. It was later shown that morphological symmetry also can be dependent on the symmetries of molecules dissolved in the growth medium (for example, Friedel and Weil, 1930). Thus, crystal morphology is the result not only of crystal structure and symmetry, but also the symmetry of the growth medium (Shafranovskii, 1957). There are therefore two general ways in which we can account for whisker growth in cubic materials: (1) anisotropy of the growth medium and (2) some sort of anisotropy that has been introduced into the crystal structure. The case of VLS growth can be classified in the first category, since the direction of whisker elongation results from the position of the liquid droplet from which the whisker crystallizes. On the other hand, whisker formation by spiral growth about a screw dislocation can occur in an isotropic growth medium and falls in the second category. In this case, the crystal structure itself possesses cubic symmetry, neglecting strain arising from the dislocation. (Although chalcotrichite morphology has led some to conclude that it has tetragonal symmetry, modern X-ray experiments suggest that it is truly cubic-see Post et al., 1981; and in prep.) However, the isotropy of the crystal as a whole is violated by the screw dislocation. It is indeed remarkable that the reduction in symmetry resulting from a single dislocation can lead to such drastic alteration of a physical property such as crystal shape. Acknowledgments We thank Dr. Shirley Turner for supplying the chalcotrichite specimen used in this study. We also thank I. D. R. Mackinnon for his critical review. This research was supported by NSF grant EAR8115790. Microscopy was performed at the Arizona State University Facility for HREM, which was established with support from NSF grant CHE7916098. References Allpress, J. G., Tilley, R. J. D., and Sienko, M. J. (1971) Examination of substoichiometric WO3-X crystals by electron microscopy. Journal of Solid State Chemistry, 3, 440-451. Amelinckx, S. (1958a) Decoration of dislocations in alkali halide whiskers. Journal of Applied Physics, 29, 1610-1611. Amelinckx, S. (1958b) Dislocations in alkali halide whiskers. In R. H. Doremus et al., Eds., Growth and Perfection of Crystals, p. 139-153. John Wiley and Sons, Inc., New York. Amelinckx, S., Bontinck, W., Dekeyser, W., and Seitz, F. (1957) On the formation and properties of helical dislocations. Philosophical Magazine, 8th Series, 2, 355-378. Barber, D. J., Harvey, K. B., and Mitchell, J. W. (1957) A new method for decorating dislocations in crystals of alkali halides. Philosophical Magazine, 8th Series, 2, 704-708. Bärner, K. and Berg, H. (1979) The growth figures of MnAs. Journal of Crystal Growth, 46, 763-770. Baronnet, A. (1972) Growth mechanisms and polytypism in synthetic hydroxyl-bearing phlogopite. American Mineralogist, 57, 1272-1293. Beardmore, P., Harwood, J. J., and Kinsman, K. R. (1980) Fiber-reinforced composites: Engineered structural materials. Science, 208, 833-840. Berezhkova, G. V., Tsvetkova, I. N., Zakharov, N. D., Rozhanskii, V. N., and Koryukin, V. 1. (1972) Growth mechanism of filamentary AIN crystals. Soviet Physics-Crystallography, 16, 848-851. Bontinck, W. and Amelinckx, S. (1957) Helicoidal dislocation lines in fluorite crystals. Philosophical Magazine, 8th Series, 2, 94-96. Broutman, L. J. and Krock, R. H. (1967) Modern Composite Materials. Addison-Wesley Publishing Co., Reading, Massachusetts. Cochran, W., Crick, F. H. C., and Vand, V. (1952) The structure of synthetic polypeptides. I. The transform of atoms on a helix. Acta Crystallographica, 5, 581-586. Curie, Pierre (1894) On the symmetry in physical phenomena, symmetry of an electrical field and of a magnetic field. (in French) Journal de Physique, 3, III, 393-415. Dash, W. C. (1958) The growth of silicon crystals free from dislocations. In R. H. Doremus, B. W. Roberts, and David Turnbull, Eds., Growth and Perfection of Crystals, p. 361-385. John Wiley and Sons, Inc., New York. Donnay, J. D. H. and Harker, D. (1937) A new law of crystal morphology extending the law of Bravais. American Mineralogist, 22, 446-467. Dowty, Eric (1976) Crystal structure and crystal growth: I. The influence of internal structure on morphology. American Mineralogist, 61, 448-459. Dowry, Eric (1977) Crystal structure and crystal growth: I. The influence of internal structure on morphology: a reply. American Mineralogist, 62, 1036-1037. Dragsdorf, R. D. and Webb, W. W. (1958) Detection of screw dislocations in αA12O3 whiskers. Journal of Applied Physics, 29, 817-819. Drum, C. M. (1965a) Axial imperfections in filamentary crystals of aluminum nitride. I. Journal of Applied Physics, 36, 816823. Drum, C. M. (1965b) Twist and axial imperfections in filamentary crystals of aluminum nitride. II. Journal of Applied Physics, 36,824-829. Drum, C. M. and Mitchell, J. W. (1964) Electron microscopic examination of role of axial dislocations in growth of AIN whiskers. Applied Physics Letters, 4, 164-165. Eshelby, J. D. (1953) Screw dislocations in thin rods. Journal of Applied Physics, 24, 176-179. Frank, F. C. (1949) The influence of dislocations on crystal growth. Discussions of the Faraday Society, 5, 48-54. Frank, F. C. (1951) Capillary equilibria of dislocated crystals. Acta Crystallographica, 4, 497-501. Friedel, G. and Weil, R. (1930) Influence of the symmetry of the medium on the symmetry of crystalline forms. Comptes Rendus Hebdomadaires des Séances de L'Académie des Sciences, 190, 243-245. Furuta, N., Itinose, H., Maruyama, N., and Ohasi, Y. (1972) Morphology and dislocation structure of tellurium whiskers grown from the vapor. Japanese Journal of Applied Physics, 11, 1113-1118. Gelles, I. L. and Binnie, W. P. (1969) High index growth of αA12O3 filamentary crystals. Materials Science and Engineering, 5, 71-92. Givargizov, E. I. (1978) Growth of whiskers by the vapor-liquid-solid mechanism. In E. Kaldis, Ed., Current Topics in Materials Science, 1, 82-145. Hartman, P. (1977) Crystal structure and crystal growth: I. The influence of internal structure on morphology: a discussion. American Mineralogist, 62, 1034-1035. Hartman, P. and Perdok, W. G. (1956) An interpretation of the law of Donnay and Harker. American Mineralogist, 41, 449459. Hasiguti, R. R., Yagi, E., Nishiike, U., and Sakai, T. (1970) An axial dislocation in copper whiskers. Journal of Crystal Growth, 7, 117-119. Hirsch, Peter, Howie, A., Nicholson, R. B., Pashley, D. W., and Whelan, M. J. (1977) Electron Microscopy of Thin Crystals. Robert E. Krieger Publishing Company, Malabar, Florida. Iijima, Sumio (1975) High-resolution electron microscopy of crystallographic shear structures in tungsten oxides. Journal of Solid State Chemistry, 14, 52-65. Kirov, G. N. and Atanasov, V. A. (1970) Cuprite whiskers and thin plates from the occurrence Bartzeto, Malko Turnovo. (in Bulgarian) Annuaire de l'Université de Sofia Faculté de Géologie at Géographie, Livre 1, Géologie, 62, 191-198. Kostov, Ivan (1968) Mineralogy. Oliver and Boyd. Edinburgh. Lehmpfuhl, G. and Uchida, Y. (1979) Darkfield and brightfield techniques for electron microscopic observation of atomic steps on MgO single-crystal surfaces. Ultramicroscopy, 4, 275-282. Lehmpfuhl, G. and Uchida, Y. (1980) Dark- and bright-field techniques for electron-microscopic observation of atomic steps on MgO single crystal surfaces. In Electron Microscopy and Analysis 1979 (EMAG79), Institute of Physics Conference Series, 52, 393-396. Post, J. R., Veblen, D. R., and Buseck, P. R. (1981) Electron microscopic study of fibrous cuprite (chalcotrichite). (abstr.) Geological Society of America Abstracts with Programs, 13, 531. Regis, M. (1969) Axial screw-dislocation absence in metallic whiskers made from solid halides. Acta Metallurgica, 17, 1281-1289. Schwoebel, R. L. (1967) A diffusion model for filamentary crystal growth. Journal of Applied Physics, 38, 1759-1765. Schwoebel, R. L. and Shipsey, E. J. (1966) Step motion on crystal surfaces. Journal of Applied Physics, 37, 3682-3686. Sears, G. W. (1953) Mercury whiskers. Acta Metallurgica, I, 457-459. Sears, G. W. (1955) A growth mechanism for mercury whiskers. Acta Metallurgica, 3, 361-366. Shaffer, P. T. B. (1967) Whiskers-their growth and properties. In L. J. Broutman and R. H. Krock, Eds., Modern Composite Materials, p. 197-216. Addison-Wesley Publishing Co., Reading, Massachusetts. Shafranovskii, I. I. (1957) Crystals of Minerals, Vol. I. (in Russian) Leningrad University. Shlichta, P. J. (1957) Torsional strain of whiskers. (abstr.) American Physical Society Bulletin, 2, 263. Thomas, Garreth and Whelan, M. J. (1959) Helical dislocations in quenched aluminium-4% copper alloys. Philosophical Magazine, 8th Series, 4, 511-527. Treuting, R. G. (1956) Torsional strain and the screw dislocation in whisker crystals. (abstr.) American Physical Society Bulletin, 1, 333. Tweet, A. G. (1958) Evidence for vacancy clusters in dislocation-free Ge. Journal of Applied Physics, 29, 1520-1522. Verma, A. R. and Krishna, P. (1966) Polymorphism and Polytypism in Crystals. John Wiley and Sons, Inc., New York. Wagner, R. S. and Ellis, W. C. (1965) The vapor-liquid-solid mechanism of crystal growth and its application to silicon. Transactions of the Metallurgical Society of AIME, 233, 10531964. Watson, J. D. and Crick, F. H. C. (1953) Molecular structure of nucleic acids. Nature, 171, 737-738. Webb, W. W. (1958) Dislocation structure of whiskers. In R. H. Doremus et al., Eds., Growth and Perfection of Crystals, p. 230-238. John Wiley and Sons, Inc., New York. Webb, W. W., Dragsdorf, R. D., and Forgeng, W. D. (1957) Dislocations in whiskers. Physical Review, 108, 498-499. Wilkins, M. H. F., Stokes, A. R., and Wilson, H. R. (1953) Molecular structure of deoxypentose nucleic acids. Nature, 171, 738-740. Wilson, A. J. C. (1949) Diffraction by a screw dislocation. Research (succeeded by Research Applied in Industry), 2, 541-542. Yamamoto, M., Gotoh, Y., and Yoshida, K. (1968) Transmission electron-microscopic study on the growth of copper whiskers by halide reduction. Journal of Crystal Growth, 3-4, 705-710. Zoltai, Tibor (1981) Amphibole asbestos mineralogy. In D. R. Veblen, Ed., Amphiboles and Other Hydrous Pyriboles, Mineralogical Society of America Reviews in Mineralogy, 9A, 237-278. Manuscript received, June 25, 1982;

|