| Home | AmMin | GMR | RiMG | Collectors Corner | Directory | Short Courses | |

|

|

|||||||

|

|

Volume 35, pages 1049-1054, 1950

CRESTMORE SKY BLUE MARBLE, ITS LINEAR THERMAL EXPANSION AND COLOR JOSEPH L. ROSENHOLTZ AND DUDLEY T. SMITH, Rensselaer Polytechnic Institute, Troy, New York. ABSTRACT Thermal studies were made of the Sky Blue marble from Crestmore, California. The coefficients of linear thermal expansion were determined from 20° to 700° C. for specimens cut with N-S, E-W and vertical geographic orientations. First cycle values are very high and indicate a condition of high strain which is largely relieved by heat treatment. The computed optic axis concentration shows a marked E-W preferred orientation which may be correlated with the geological structure. The sky-blue color is attributed to residual strain. INTRODUCTION Thermal studies of oriented specimens of Yule marble (1) have indicated the possibility of correlating linear thermal expansion with the stresses involved in deformational processes. Dr. Eleanora B. Knopf, in discussing this question with Professor A. O. Woodford of Pomona College, suggested that such an investigation of the Sky Blue marble found at Crestmore might present interesting results. Through the kindness of Professor Woodford, several large samples were collected in the field, some of which were oriented as to dip and strike. The grain size is so varied that there was hope of obtaining a few sufficiently large grains to withstand the rigors of cutting oriented specimens and thereby permit single crystal studies to be made. Unfortunately, none could be obtained large enough for this purpose and, through Professor Woodford's efforts, suitable specimens were selected having a 2-3 mm. grain size. Test specimens were cut from a single field sample taken from the Commercial Quarry, Crestmore, California, at about 900' elevation, 2700' East and 1500' North, Riverside Cement Company coordinates. The field sample surface dipped 27° E. and the strike was N 10° E. Test specimens having N-S, E-W., and vertical orientations were cut from this sample. PROCEDURE The method used for measurement of the coefficient of linear thermal expansion, a, has been fully described (1). In order to determine the effect of heat treatment upon the relief of permanent strain, the two cycle heating-cooling technique was followed. Experience with Yule marble indicated the possibility of introducing what appear to be thermal strains in the vicinity of 350°. In an attempt to eliminate this possibility, a series of oriented specimens were first studied cyclically to 400° C. The length recovery after the second heating cycle was much greater than it should have been had the deformational strains been removed. It was therefore decided to proceed exactly as in the case of the Yule marble and to use two heating-cooling cycles to 700° C. The values of the coefficients of thermal expansion are given in Table 1 for each geographic orientation and for both heating-cooling cycles.

TABLE 1. COEFFICIENTS OF LINEAR THERMAL EXPANSION OF CRESTMORE SKY BLUE MARBLE First Heating-Cooling Cycle

Second Heating-Cooling cycle

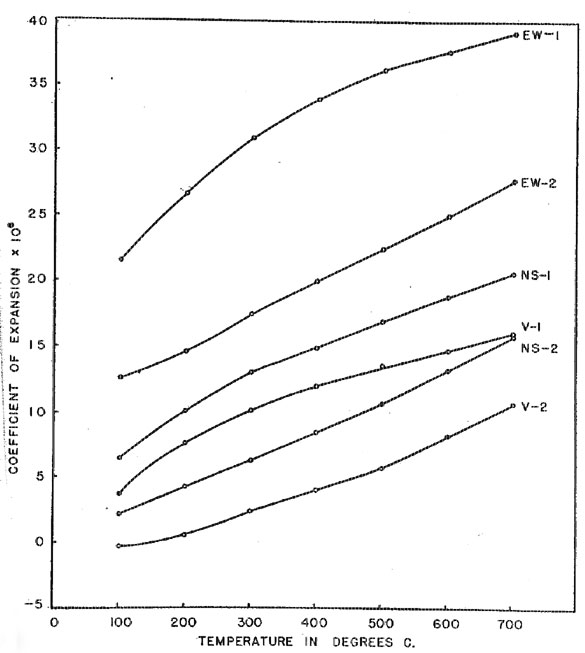

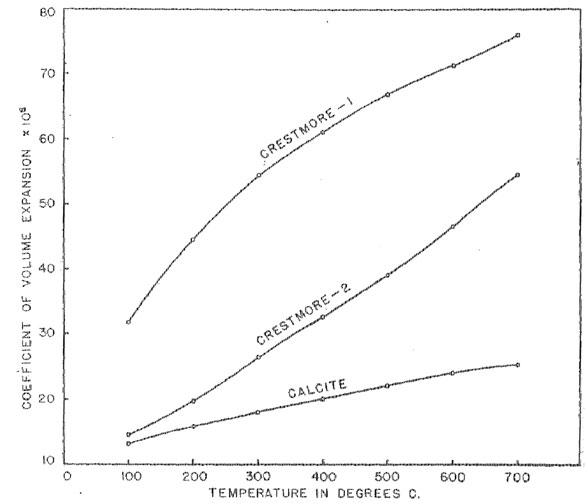

The curves shown in Fig. 1 indicate that the rate of increase of α more regular after the strains are relieved during the first heating-cooling cycle. For comparison with a calcite single crystal, the calculated volume expansion coefficients are shown in Fig. 2. The correspondence at 100° is very good between calcite and second cycle marble. This is an indication that structural strains have been largely removed. As the temperature is increased, however, the volume change in the marble diverges appreciably. This may well be due to the introduction of strains induced by heating because of the marked anisotropy of thermal expansion of calcite. ORIENTATION OF THE MARBLE Woodford (2) has found that, while the structure at Crestmore is quite certain, there are some observable suggestions of bedding having an easterly dip. He indicates* that, for the area from which the field specimen was obtained, any expansive force related to the intrusion of the quartz monzonite porphyry would probably have been directed approximately in the same direction as the normal to the problematical bedding planes in the marble. This indicates a maximum stress in the E-W direction whether thermal or deformational stresses or both are involved.

The authors have recently made studies of linear thermal expansion of compressed cylinders of magnesium and medium soft steel (3). They found that a increases in a stress range beginning at the yield point and continuing until extensive plastic deformation occurs, after which it begins to decrease. It is inferred, therefore, that a high value of a may he correlated with a large stress history and, since a for Sky Blue marble is a maximum in the E-W orientation, it is logical to assume that this was the direction of maximum stress. Although the structural details are not clear, this assumption corresponds with the available field facts and may be used to point the way in the evaluation of obscure field information. As for preferred grain orientation, calculations based upon the coefficients obtained from the second heating-cooling cycle at 20°-100° C. indicate that 59 per cent of the grains have their optic axes concentrated in the E-W direction, with 25 per cent N-S and 16 per cent vertical. Although these calculated concentrations are based upon the assumption that only c or a orientations exist in each geographic direction, the results show the decided preference in the E-W direction. THE COLOR OF SKY BLUE MARBLE The name of this recrystallized limestone is most descriptive of its color. Of particular interest is the fact that the blue marble makes an irregular envelope 100 to 150 feet thick, about an intrusion of quartz monzonite porphyry; it is, in turn, enveloped by white marble. The blue marble, which appears quite uniform to the unaided eye, shows microscopic black segregations scattered throughout. Segregations which have been weathered slightly are surrounded by ferric oxide stains. Small pieces of the blue marble were heated to various temperatures, beginning at 100° C. and increasing by 25° intervals. The samples were held at each temperature for 30 minutes. The first observable fading was produced by heating at 225° C; it was more pronounced at 250° and was complete at 275°, resulting in a light cream-white color. If the heating rate is not sufficiently slow, the blue marble samples shatter explosively into white cleavage fragments in the vicinity of 275 ° C. It seemed advisable to ascertain whether the color changes noted might be due to chemical effects. Professor Arthur A. Burr of Rensselaer Polytechnic Institute kindly agreed to make spectrographic and powder x-ray examinations of the blue marble as well as specimens which were heated to 275° and 700° C., in order to seek out possible coloring constituents. The spectrographic examination showed a small amount of iron and no other coloring elements; furthermore, the concentration of iron was the same in all three specimens. No irregularities of any kind were revealed by the x-ray examination. While structural strain is readily shown by x-ray, in this case the strain was doubtless relieved by the pulverization. It is obvious that the color change induced by heat treatment under 300° C. was not due to chemical changes. The only apparent reason for the blue color appears to be residual strain which is relieved by heating. It is perfectly reasonable to assume that structural changes due to thermal or deformational stresses may produce pronounced color effects. This condition may be brought about in some alloys by cold working processes and it may well be that particular stress conditions can produce color changes in calcite. This raises the large question as to why most marbles are not blue. Disregarding definite coloring constituents, stress conditions are so variable, both as to character and intensity, that the answer cannot be known until the specific conditions which are color inducing are discovered. ACKNOWLEDGMENTS This research was made possible by assistance from the Rensselaer Polytechnic Institute Research Fund. The authors are especially grateful to Professor Woodford for collecting the specimens and for information lie has supplied relative to field observations. They also are indebted to Professor Burr for his spectrographic and x-ray examinations of the marble specimens. REFERENCES 1. ROSENHOLTZ, J. L., AND SMITH, D. T.: Am. Mineral., 34, 846-854 (1949) 2. WOODFORD, A. O.: Calif. Jour. Mines and Geology, Report XXXIX, State Mineralogist, July 1943, 33.3-365. 3. ROSENHOLTZ, J. L., AND SMITH, D. T.: J. Appl. Phys., 21, 396-399 (1950). NOTE * personal communication. |